I do a lot of hobby 3D printing. Probably too much. But that is OK. I am retired from “real” work and need a challenging avocation.

I have encourage only a few people to get involved. I say “only” because 3D printing is so much more than buying the printer. You can also build your printer from scratch. But that is another story for another time. But here are a few 3D print facts:

The commercial “additive manufacturing and “rapid prototyping” using 3D printing has been in existence since the 1980’s. It was very expensive and only major manufactures were involved.

The hobby of 3D printing actually got it’s start from the folks who built their own machines.The common boast at the time was to build an 3D printer that could in turn be used to build another. The term RepRap (a contraction of REPlicating RAPid prototyper) arrived in 2005 in England and the concept rapidly spread.

It was probably another 5 years before the open source software and good hardware design became widespread.

You will find plenty more information doing a web-search for REPRAP.

My point is the HOBBY of three dimensional additive manufacturing began (and remains) a very technical and hands on with understanding the operation, maintaining and repairing faults and failures with the printing machinery, as well as the joy of creating a 3D object.

Once you own a machine, it is all up to you to maintain it and keep it operating. It is NOT a home appliance. There are NO “Maytag Repairman” one can call to get your printer running after it quits working. Oh, yes! It will be “quitting” and needing YOUR skills in trouble-shooting and then repair.

The hobby is not the tool, or printer. The hobby is what the tool let’s me create from an idea in my mind.

I am kind of a “lone wolf” hobbyist. I have the needed problem solving skills. It’s why I can enjoy fixing this specialized and technical tool. I think a club group or knowing others in a hobby is a good idea getting started.

When it is running properly electrically and mechanically, there are at least 200 variables one needs to understand in great detail, to “set up” to use 3D PRINTING tool for that perfect print.

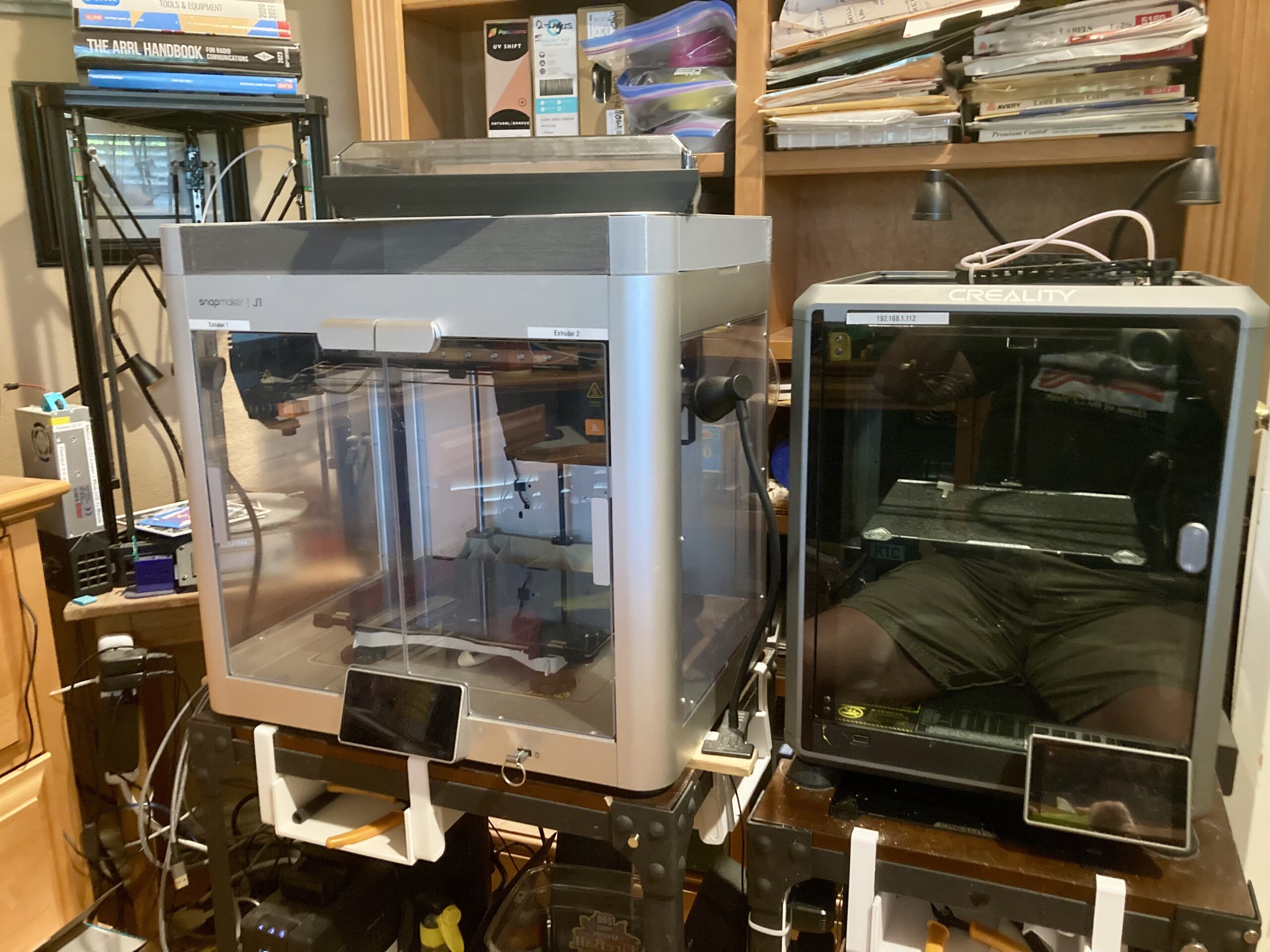

Wonderfully designed and complex hobby grade printers are now widely available. Check out amazon.com but there are a great many more vendors and all the main brands have their own web presence. It’s easy to get information. No need to get into details here.

First “Things” to print are also not much of a problem. The early promotors of the hardware immediately realized the printer is no good if there are no designs to print. Ready to print files are widely available. Again, search the WWW. Some folks are happy just printing the perhaps one million existing designs

One facet of the 3D printing hobby I enjoy is the DIY design of the unique items to print. One must acquire or have some mastery of the CAD drawing process or 3D “art” drawing systems such as Z-Brush. Creative drawing systems are like another or separate hobby within the hobby.

In my opinion, not creating my own designs make me just a machine operator. I love the creative “from scratch” design aspect of 3D printing.

Gaining some traction with some hobbyist is digital object scanners that create “point clouds” that can be used to create printable files for 3D duplicates of what was scanned. I haven’t traveled that route (yet).

There are many side paths to explore that can benefit from association with additive manufacturing, making “things” with 3D printing.

The one big caveat I want to again stress is that a 3D printer is not a kid’s toy, nor is it a trouble free appliance or lifetime-use, hard working, never failing, shop tool.

It’s a very sophisticated and technical, electro-mechanical computer device. Sometimes very “fussy” in its operation. It’s going to need and demand tender loving care and maintenance, far above your average workshop power tool. Also a clean air-conditioned and DRY place to live and operate.

But if one does have the creative “right stuff” and you love hands-on technical problem solving and occasional tool (printer) repair as part of the experience of creating tangible items, you are going to love (most of the time) the 3D printing hobby.

Every day may not be perfect but creating the perfect part makes it worth the experience.

Hint: Start small and simple and work your way to the hard stuff. Walk don’t run. It’s not a race. It’s an experience that requires development.